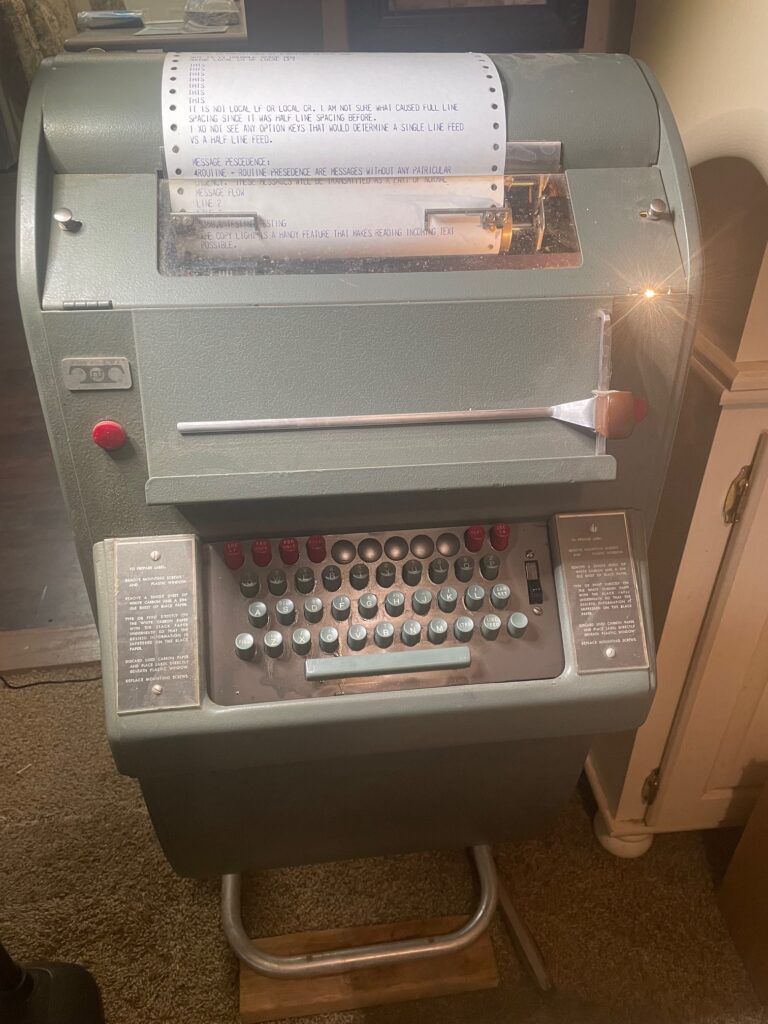

I fully assembled the Model 28 and it looks great. It is working in ‘test’ mode, where the device ignores the signal loop and behaves like a typewriter. It is a bit loud, however.

When I got it, there were foam panels stuck inside the housing, but the foam had thoroughly disintegrated. This foam was there to deaden some of the noise this machine makes when operating. Replacing this isn’t straightforward, since these haven’t been made in decades, and these likely wouldn’t have been a part offered by Teletype in any case.

Cleaning the interior of the housing was quite a chore. The foam was easy to remove as it turned to powder when touched, but the adhesive was some tough stuff. I used citrus oil based GooGone which was effective, but needed significant soak time to soften the adhesive, then quite a bit of scrubbing to remove it. It took a couple of cycles of this to remove most of the old adhesive. To finish, I scrubbed with dawn dish soap to remove the citrus oils, then finished with simple green.

I thought through some ways to replace this material, such as quilting something. It occurred to me that carpet squares may be just the material for this. They are light, somewhat rigid, and I was able to find a decent color approximation.

Making the templates from scratch paper and cutting the carpet is fairly straightforward, but the adhesive on the carpet squares isn’t sufficient for a vertical installation. They do offer a spray adhesive with the carpet squares that seems highly effective. When using it, it sticks quite firmly very quickly so placement has to be accurate. These carpet squares should be durable and dampen the noise of the machine without looking out of place.

Next project is the loop interface to a computer provided by Deramp – Model 15 Interface. It will take quite a bit of assembly, so I don’t anticipate a fast build, but with a signal loop I’ll be able to use this close to its original purpose.