I used the TA-312 a lot while on active duty, really quite a whole lot. At the time I really didn’t appreciate just how useful and rugged these phones are.

The US Army recently removed these from inventory (last decade or so), which I think was a mistake given what they can do. They provide reliable communications for an area and do not give an interceptable signal like radios do. They are compact, can take a beating, and are quite simple to understand. I found a pair of these recently and decided to pick them up. One of them had a ringer that wouldn’t ring, so I did have to do some repair.

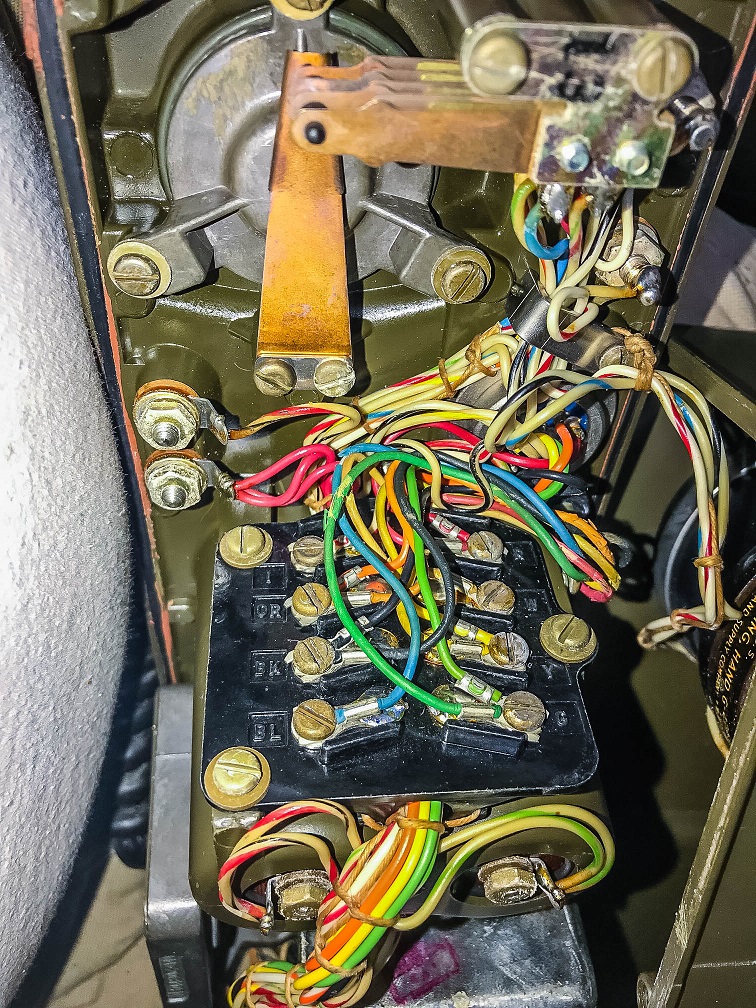

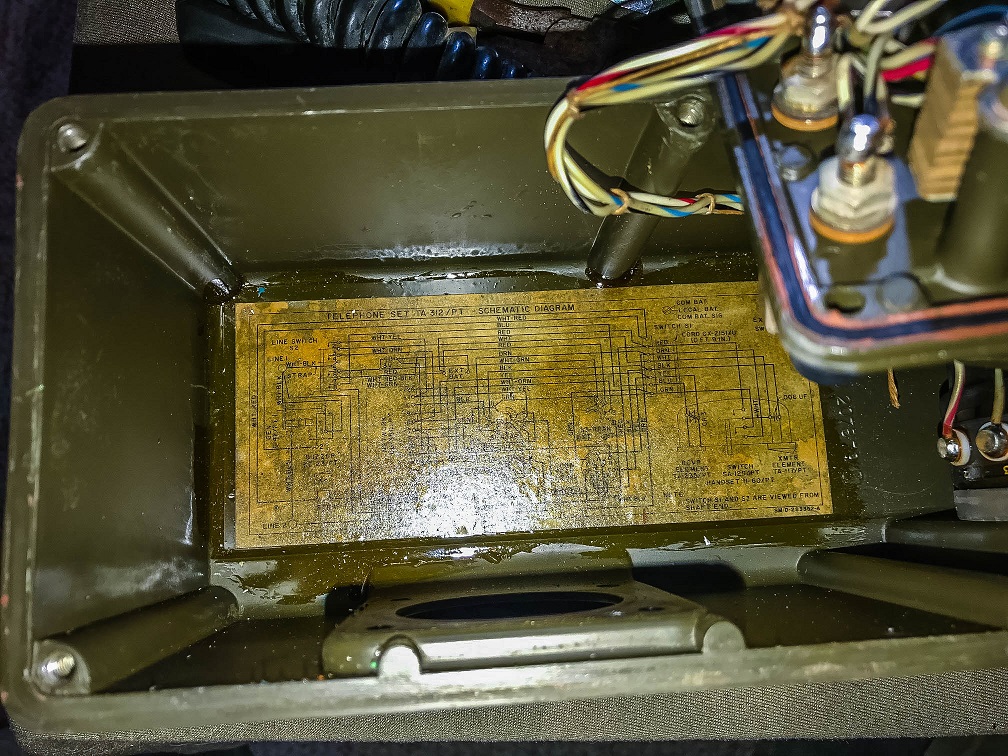

Despite using these phones extensively, I don’t believe I have ever seen the inside. I took my time, consulted what info I could find on the internet (including Signal Center | U.S. Army Signal Corps field telephones and switchboards) and identified what I needed to fix the phone with a broken ringer. The ringer is part “Buzzer BZ-23/PT” and is held in place by the 4 external screws and a small pin connecting the ringer assembly to the ringer volume control knob. There are two wires that require solder connections as well and are color coded so it is clear what goes where. This job looked intimidating at first, but was actually quite straightforward with patience, lots of photos, and referencing the SignalCenter website.

I got handset spaghetti cables and other miscellaneous parts from SignalCenter.com and the ringer/buzzer from Fair Radio Sales – Electronic Military and Industrial Surplus.

Replacing the handset spaghetti cable took some patience, but also was fairly straightforward to do. I took lots of photos but the individual cables are color coded so it actually wasn’t hard to do at all. The spaghetti cable has a small hook on either end that prevents the cable from backing out when it is pulled on. Fishing the small cables through the handset and phone body was not as difficult as I expected.

I don’t anticipate these phones being incredibly useful for amateur radio events, but they should be a very interesting addition as part of the overall setup I have when people visit the station in the field.

Thank you to Signal Center | U.S. Army Signal Corps field telephones and switchboards for the TA-312 information and parts and Fair Radio Sales – Electronic Military and Industrial Surplus for the “buzzer”.